Steel racks designed for medical equipment in Holland, Ohio leverage high-quality materials and CNC machining to offer custom, durable, and efficient storage solutions. CNC machining enables precise creation of tailored rack components, accommodating diverse equipment sizes and shapes while meeting healthcare industry standards. This technology enhances product stability, streamlines manufacturing processes, reduces costs, and ensures consistent quality, making it ideal for medical sector needs, particularly in transport of sensitive devices. Local businesses specializing in custom CNC-machined packaging components are transforming the industry in Holland, Ohio, providing advanced solutions that improve efficiency and productivity.

“Revolutionize medical equipment storage with the unparalleled strength and versatility of steel racks. In today’s fast-paced healthcare environment, efficient organization is key. Discover how CNC machining, a game-changer in the packaging industry near Holland, Ohio, transforms custom medical rack components.

From durable materials to design flexibility, these racks offer advantages tailored to the medical sector. Enhance storage and streamline operations with state-of-the-art CNC-machined packaging solutions, providing benefits that traditional methods can’t match.”

- Understanding Steel Racks for Medical Equipment: Materials and Durability

- CNC Machining: The Modern Approach to Custom Medical Rack Components

- Advantages of CNC-Machined Packaging in the Medical Sector

- Design Flexibility: Creating Racks to Meet Specific Medical Equipment Needs

- Implementing Steel Racks: Streamlining Medical Facility Storage and Organization

Understanding Steel Racks for Medical Equipment: Materials and Durability

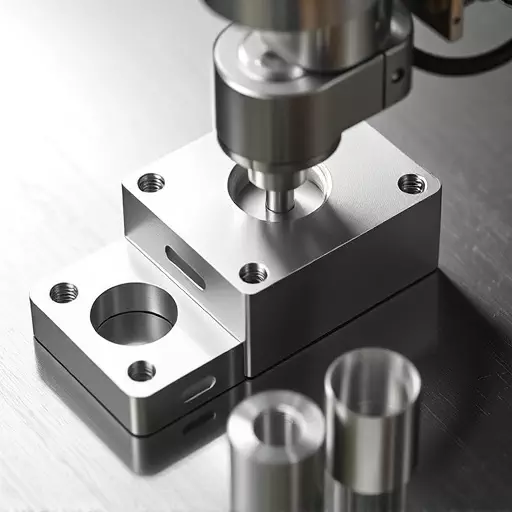

Steel racks for medical equipment are designed to meet the stringent demands of healthcare facilities. The materials and construction methods play a crucial role in ensuring their durability, which is essential in maintaining sterile environments. High-quality steel, often enhanced through processes like CNC machining, forms the backbone of these racks. CNC machining, a precise manufacturing technique, allows for the creation of custom cnc-machined packaging components tailored to specific medical equipment needs. This level of customization offers numerous benefits of cnc machining in packaging, such as improved organization and accessibility within healthcare settings.

The steel used in their construction is chosen for its resistance to corrosion, a critical factor in environments where moisture and diverse chemical solutions are common. CNC machining techniques enable the creation of intricate designs, ensuring each rack can accommodate various medical equipment sizes and shapes. This precision manufacturing also guarantees the longevity of the racks, making them reliable investments for healthcare providers in Holland, Ohio, and beyond.

CNC Machining: The Modern Approach to Custom Medical Rack Components

CNC Machining offers a modern and precise approach to crafting custom medical rack components in Holland, Ohio. This advanced technology allows for intricate designs and exact specifications, ensuring that each part meets the rigorous standards required in the healthcare industry. By utilizing CNC machines, manufacturers can produce complex packaging elements with exceptional accuracy and efficiency.

The benefits of CNC machining in this sector are numerous. It enables the creation of tailored components, enhancing product stability and security within medical storage racks. This precision engineering results in improved overall equipment effectiveness, reducing downtime and maintenance needs. Moreover, CNC-machined parts contribute to streamlined manufacturing processes, allowing for faster production times and cost-effectiveness, which are vital considerations for the dynamic packaging industry.

Advantages of CNC-Machined Packaging in the Medical Sector

The medical sector demands precision and compliance with stringent standards, making CNC-machined packaging an ideal solution. Custom CNC machining allows for the creation of intricate and exact components tailored to specific medical equipment requirements. This technology ensures consistent quality and reduces human error in manufacturing, a critical factor in the healthcare industry where accuracy is paramount.

CNC-machined packaging offers numerous benefits, including improved efficiency, reduced production times, and enhanced product consistency. In Holland, Ohio, for instance, businesses specializing in CNC machining provide advanced solutions for medical packaging needs. These custom components can be designed to accommodate unique equipment shapes and sizes while adhering to regulatory standards, ensuring the safe transport of sensitive medical devices.

Design Flexibility: Creating Racks to Meet Specific Medical Equipment Needs

Implementing Steel Racks: Streamlining Medical Facility Storage and Organization