Steel racks enhance workflow efficiency and security in Holland, Ohio's industrial facilities, particularly those involved in CNC machining for the packaging industry. Custom CNC-machined packaging parts offer unparalleled precision, complex designs, fast turnaround times, and consistent quality, making them a game-changer in today's competitive market. These benefits drive manufacturer success, customer satisfaction, and enhanced product protection.

Steel Racks: The Foundation for Efficient Industrial Equipment Management

In today’s fast-paced industrial landscape, streamlined equipment organization is paramount. Steel racks emerge as a robust solution, providing both structural support and strategic storage for diverse machinery. This article explores the pivotal role of steel racks in optimizing space, enhancing accessibility, and ultimately driving operational efficiency. We delve into the advantages of custom CNC-machined packaging components specifically tailored to meet the unique demands of Holland, Ohio’s thriving packaging industry, highlighting the transformative benefits of this advanced machining technique.

- Understanding Steel Racks and Their Role in Industrial Equipment Organization

- The Advantages of CNC Machining for Custom Packaging Components in Holland, Ohio

- How CNC Machining Enhances the Packaging Industry: A Case Study

Understanding Steel Racks and Their Role in Industrial Equipment Organization

Steel racks are an essential component in any industrial facility, especially for those involved in complex processes like CNC machining for industries such as packaging in Holland, Ohio. These racks serve as a sophisticated organization system, meticulously designed to store and manage various types of equipment, tools, and components. Custom CNC-machined packaging components, for instance, can be efficiently housed on these racks, ensuring easy accessibility for production teams.

By implementing steel racks, industrial plants reap numerous benefits, particularly in the context of CNC machining for packaging. The structured layout enhances workflow efficiency, enabling faster setup and changeover times between different packaging processes. Additionally, these racks offer a secure environment by safeguarding valuable equipment and components from damage, theft, or misplacement—a critical advantage when dealing with precision machinery and delicate parts.

The Advantages of CNC Machining for Custom Packaging Components in Holland, Ohio

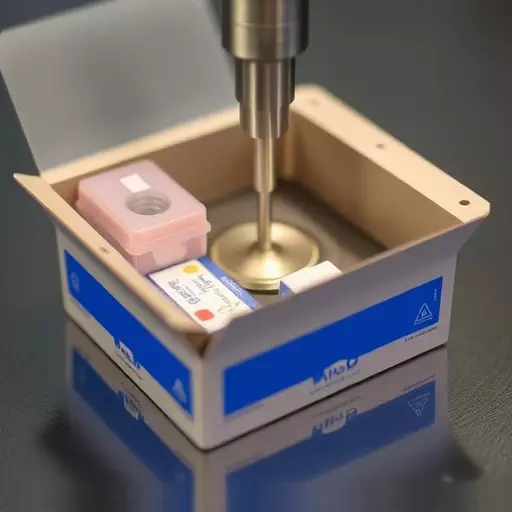

In Holland, Ohio, CNC machining has emerged as a game-changer for the packaging industry, offering unparalleled precision and efficiency when crafting custom components. This advanced manufacturing process involves using computer-controlled machines to cut, shape, and form materials with extreme accuracy, making it ideal for creating unique, tailored parts. For businesses seeking customized packaging solutions, CNC machining provides an array of benefits.

One of its key advantages is the ability to produce intricate designs and complex geometries that would be challenging or impossible to achieve with traditional manufacturing methods. This precision ensures that each packaging component meets specific customer requirements, leading to enhanced product protection and presentation. Moreover, CNC machining allows for fast turnaround times, enabling companies to quickly adapt to changing market demands and stay ahead of the competition.

How CNC Machining Enhances the Packaging Industry: A Case Study

In today’s competitive market, the packaging industry constantly seeks innovative solutions to enhance product presentation and protect goods during transportation. This is where CNC machining for packaging industry Holland Ohio plays a pivotal role. By utilizing custom CNC-machined packaging components, manufacturers can achieve unparalleled precision and efficiency in creating specialized cases, trays, and inserts tailored to specific product requirements.

The benefits of cnc machining in packaging are multifaceted. Firstly, it enables the production of complex geometries and intricate designs that would be challenging or impossible with traditional methods. Secondly, CNC machining ensures consistent quality and accuracy, reducing waste and improving overall productivity. Moreover, this technology allows for rapid prototyping and customization, enabling businesses to swiftly adapt to changing market demands and consumer preferences. In a dynamic industry like packaging, these advantages translate into increased competitiveness and customer satisfaction.