Modular steel shipping racks enhanced by CNC machining technologies are transforming the packaging industry in Holland, Ohio. Custom CNC-machined components offer unparalleled versatility and efficiency, addressing modern supply chain demands. Benefits include precise manufacturing for stability, optimized space utilization, unique design features like integrated casters, and specialized compartments. These innovations revolutionize packaging operations, boosting speed, organization, and product protection. By leveraging CNC machining, Holland is establishing itself as a hub for cutting-edge packaging solutions, providing local businesses with a competitive edge through faster production, reduced waste, and improved product quality.

“Modular steel shipping racks are transforming the landscape of the packaging industry. These versatile structures play a pivotal role in efficient storage and transportation, especially with the rise of e-commerce. This article delves into the understanding and benefits of these racks, highlighting their structural advantages.

We explore how custom CNC-machined packaging components offer unparalleled efficiency and flexibility, meeting unique industry needs. Furthermore, we shine a spotlight on Holland, Ohio, as a game-changer for local businesses adopting CNC machining for packaging, revealing its significant impact.”

- Understanding Modular Steel Shipping Racks: Their Role in the Packaging Industry

- The Advantages of Custom CNC-Machined Packaging Components for Efficiency and Flexibility

- Exploring CNC Machining for Packaging in Holland, Ohio: A Game-Changer for Local Businesses

Understanding Modular Steel Shipping Racks: Their Role in the Packaging Industry

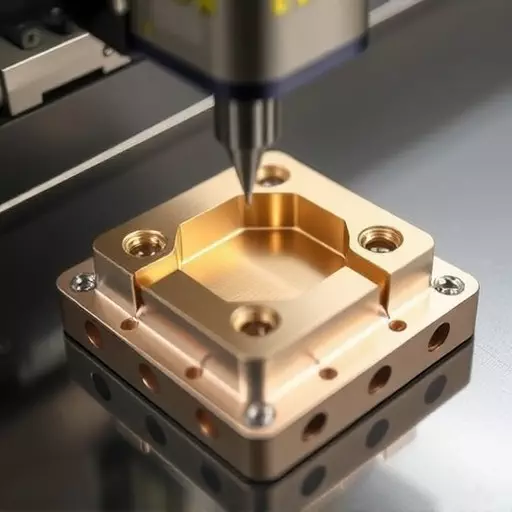

Modular steel shipping racks are transforming the way businesses handle and store goods, particularly within the packaging industry. These innovative storage solutions offer unparalleled versatility and efficiency, catering to the dynamic nature of modern supply chains. By leveraging CNC machining technologies, manufacturers in Holland, Ohio, can create custom cnc-machined packaging components tailored to specific product dimensions and handling requirements.

The benefits of CNC machining in the packaging sector are multifaceted. It enables precise manufacturing, ensuring each rack component fits perfectly with others, enhancing overall stability and durability. This precision also translates into optimized space utilization, allowing for denser packing without compromising safety or accessibility. Moreover, CNC-machined racks can be designed with unique features like integrated casters for easier mobility or specialized compartments for handling fragile items, thereby revolutionizing packaging operations in terms of speed, organization, and product protection.

The Advantages of Custom CNC-Machined Packaging Components for Efficiency and Flexibility

In today’s fast-paced and competitive market, efficiency and flexibility are paramount for any business, especially those in the packaging industry. Custom CNC-machined packaging components offer a significant advantage over traditional manufacturing methods. By leveraging advanced CNC machining technologies, companies can create precise, tailored solutions that perfectly fit their unique product requirements. This level of customization ensures optimal space utilization within shipping racks, reducing material waste and improving overall efficiency.

The benefits extend beyond spatial optimization. CNC machining in Holland, Ohio, allows for intricate and complex designs to be produced with precision and speed. This technology enables businesses to adapt quickly to changing market demands, offering greater flexibility in terms of product packaging and presentation. With custom CNC-machined components, the possibilities are endless, from creating specialized dividers and inserts to designing innovative protection mechanisms for fragile items, thereby enhancing the overall functionality and effectiveness of steel shipping racks.

Exploring CNC Machining for Packaging in Holland, Ohio: A Game-Changer for Local Businesses

In Holland, Ohio, businesses are discovering a revolutionary approach to packaging through the adoption of CNC machining. This advanced manufacturing technique offers unprecedented precision and efficiency in creating custom CNC-machined packaging components. By leveraging CNC technology, local companies can now produce intricate and precise parts tailored to their unique product requirements, marking a significant shift in the packaging landscape.

The benefits of CNC machining in the packaging industry are manifold. It enables faster production times, reduces material waste, and enhances overall product quality. Moreover, it allows for complex designs and innovative shapes that traditional manufacturing methods might struggle with. This game-changer is transforming local businesses by providing them with a competitive edge, ensuring they stay ahead in a dynamic market. With the ability to quickly adapt to changing demands, Holland, Ohio, is establishing itself as a hub for cutting-edge packaging solutions.