CNC machining is reshaping the steel rack technology landscape in Holland, Ohio, by enabling precise and efficient custom packaging component production. This advanced manufacturing process offers numerous benefits to local businesses, including improved product quality, reduced waste, and enhanced operational efficiency. By adopting CNC machining for their packaging needs, manufacturers in Holland, Ohio, are driving innovation, optimizing production times, and gaining a competitive edge in the market.

The future of steel rack technology is here, driven by innovations that promise to transform warehousing and logistics. This article explores how CNC machining, a game-changer in the packaging industry, particularly in Holland, Ohio, is revolutionizing storage solutions. We delve into the evolution of steel rack systems, highlighting trends like lighter materials, modular designs, and smart connectivity. Learn about the pivotal role of CNC machining in creating custom, tailored packaging components, enhancing product protection, and boosting customer satisfaction. Discover the benefits of increased speed and precision, as well as a future integration of advanced steel racks with AI-driven automated packaging lines and smart warehouses.

- The Rise of CNC Machining in the Packaging Industry

- – Exploring the application of CNC machining in Holland, Ohio, and its impact on the packaging sector.

- – Highlighting the advantages of custom CNC-machined components for efficient and precise packaging solutions.

- Innovations in Steel Rack Technology

- – Discussing the evolution of steel rack systems and their role in modern warehousing and logistics.

The Rise of CNC Machining in the Packaging Industry

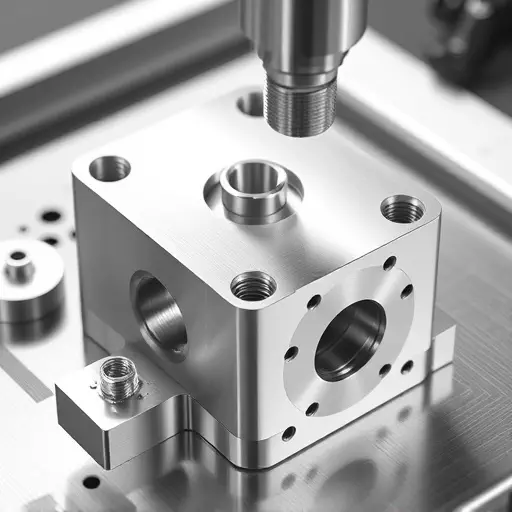

The steel rack technology landscape is evolving rapidly, and one key player leading this transformation is CNC (Computer Numerical Control) machining. This advanced manufacturing process has significantly impacted various industries, including the packaging sector in Holland, Ohio. By utilizing custom CNC-machined packaging components, manufacturers are unlocking numerous benefits that drive efficiency and innovation.

CNC machining for the packaging industry offers precise and repeatable manufacturing of intricate parts. Customization is at its core; businesses can design and produce unique steel rack components tailored to specific packaging needs. This level of customization enhances product quality, ensuring every detail meets exacting standards. Moreover, CNC machining streamlines production, reduces waste, and improves overall productivity, making it an indispensable asset for modern packaging operations in the region and beyond.

– Exploring the application of CNC machining in Holland, Ohio, and its impact on the packaging sector.

In Holland, Ohio, the application of CNC (Computer Numerical Control) machining has revolutionized the packaging sector. This advanced technology enables the precise and efficient manufacturing of custom CNC-machined packaging components, tailored to meet specific product requirements. By leveraging CNC machining, local manufacturers can produce intricate designs and complex shapes that were once challenging or impossible with traditional methods.

The benefits of CNC machining in the packaging industry are multifaceted. It enhances productivity by automating repetitive tasks, ensuring consistent quality and reducing human error. Moreover, CNC-machined components offer improved dimensional accuracy and precision, leading to better product protection and enhanced overall packaging aesthetics. With its ability to handle a wide range of materials, CNC machining also contributes to cost reduction and material waste minimization, making it an increasingly preferred choice for forward-thinking manufacturers in Holland, Ohio, and beyond.

– Highlighting the advantages of custom CNC-machined components for efficient and precise packaging solutions.

In today’s competitive market, efficient and precise packaging solutions are paramount for businesses looking to optimize their operations. Custom CNC-machined components emerge as a game-changer in this landscape. By leveraging advanced CNC machining technologies, manufacturers can produce tailored packaging elements that seamlessly fit specific product requirements. This level of customization ensures not just enhanced structural integrity but also streamlined assembly lines, reducing waste and minimizing production time.

Located in Holland, Ohio, the heart of the packaging industry, these custom CNC-machined components are transforming the way products are packaged and protected during transit. The benefits extend beyond straightforward cost savings; they include improved product presentation, better protection against damage, and enhanced brand reputation through innovative and high-quality packaging solutions. This precision engineering not only caters to diverse product needs but also sets a new standard for efficiency and sustainability in the industry.

Innovations in Steel Rack Technology

The future of steel rack technology is bright, driven by advancements in manufacturing processes like CNC machining. Holland, Ohio-based companies are at the forefront of this revolution, utilizing CNC machinery to produce custom, precision-engineered packaging components tailored to specific industry needs. This innovation offers numerous benefits for the packaging sector, including improved efficiency and reduced waste due to precise cut-outs and intricate designs that traditional manufacturing methods struggle to match.

By leveraging CNC machining, these progressive companies are not only enhancing product quality but also streamlining production times. Custom cnc-machined packaging components can be designed and fabricated swiftly, allowing businesses to respond promptly to dynamic market demands and competitive pressures. This agility in design and production is a game-changer for the industry, ensuring that manufacturers stay ahead of trends and consumer preferences.

– Discussing the evolution of steel rack systems and their role in modern warehousing and logistics.

Steel rack systems have undergone a remarkable evolution over the years, transforming from simple storage solutions to sophisticated elements in modern warehousing and logistics. These systems are no longer just metal frames; they’ve become highly tailored, efficient, and versatile components designed to optimize space utilization and streamline operations. The integration of CNC machining technology has played a pivotal role in this evolution. Custom CNC-machined packaging components, for instance, offer unparalleled precision and customization, enabling manufacturers to create complex structures that enhance product stability and security.

This advancement is particularly notable in the packaging industry, where the demand for efficient and innovative storage solutions is ever-growing. The benefits of CNC machining are multifaceted: it improves production speed by automating processes, ensures superior quality control through precise measurements, and allows for the creation of intricate designs that address unique product needs. As a result, warehouse managers in Holland, Ohio, and beyond can leverage these custom steel rack systems to enhance their operations, making them more agile, cost-effective, and competitive in the dynamic world of logistics.